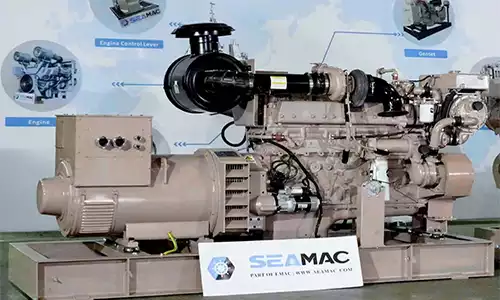

K38 – DM969 Auxiliary Engine

CCEC K38-DM969 (1800 RPM) Marine Auxiliary Engine is V Type 12-Cylinder, 38 liters four-Strokes Engine with 159 mm (6.25 in) Bore and 159 mm (6.25 in) Stroke.

K38-DM969 Marine Auxiliary Engine Equipped with Direct Injection CMI STC Fuel System, Comes with Turbocharged & Water-Air Intercooler, This Marine Diesel Engine Complies with IMO-NOx Requirements of the International Maritime Organization (IMO). The Overload Capacity Power at 1800 RPM of CCEC K38-DM969 Marine Auxiliary Engine is 1430 HP (1066 kW), The Prime Power at 1800 RPM of CCEC K38-DM969 Marine Auxiliary Engine is 1300 HP (969 kW). The Maximum Torque of the Engine at 1800 RPM is 5657 N.m.

CCEC provides both heat exchanger cooling and radiator cooling marine auxiliary engines, which mainly using for marine main generator and marine emergency generator.

For the emergency generator set applications, we provide additional options for customers such as dual starter motor system (we provide both electric and spring starter motor for customers), which are required by most of international classifications.

All of CCEC marine auxiliary engine are comes with dry type exhaust system, which means dry type exhaust manifold and dry type turbocharger, SeaMac provides upgrading services for water-cooled exhaust system, which modify dry type exhaust system into water-cooled exhaust system, which are quite important and often requested by passenger boat projects.

Advantages of CCEC K38 – DM969 Auxiliary Engine

-

Four-valve per cylinder design optimizes air/fuel mixture. Improves combustion and emissions. High-strength alloy casting, can withstand higher impact. Each cylinder has a cover, and the oil supply and oil return pipelines are drilled inside the cylinder head, with a simple structure and easy maintenance. Dual camshaft design for precise control of valve and injection timing.

-

Integral crankshaft made of high-strength forged steel, rounded corners and crank necks are subjected to induction hardening treatment, and the fatigue strength of the crankshaft is higher. The piston is made of aluminum alloy casting, and the design of the w-shaped head and the barrel-shaped skirt can compensate for thermal expansion and cold contraction to ensure a good fit.

-

High-capacity gear pumps provide pressurized oil to lubricate bearings and cool pistons. All pressure lubricating oil passages are drilled in the cylinder block and inside the cylinder. Oil cooler, full flow filter.

Technical Specifications

Basic Introduction of CCEC K38 – DM969 Marine Auxiliary Engine

| Engine Model: | K38 – DM969 |

| Engine Type: | V-12 Cylinders / 4 Stroke / 4 Valve |

| Displacement: | 38 L |

| Rated Power / Speed: | 969 kW @ 1800 RPM |

| Aspiration Method: | Turbocharged & Water-Air Intercooler |

| Emission Standard: | IMO Tier II |

| Bore * Stroke: | 159 mm * 159 mm |

| Packing Size (L * W * H): | 2210 mm * 1320 mm * 1651 mm |

| Dry Weight: | 3723 kg |

| Lead Time: | 15-30 Working Days |

| Payment Terms: | T / T ,L / C |

Engine Model |

Advertised Power |

Aspiration |

Compression Ratio |

Fuel System |

| K38 – DM746 | 746 kW (1000 HP) @ 1500 RPM | Turbocharged / LTA | 13.9 : 1 | PT |

| K38 – DM821 | 821 kW (1100 HP) @ 1800 RPM | Turbocharged / LTA | 13.9 : 1 | Direct Injection CMI PT |

| K38 – DM880 | 880 kW (1180 HP) @ 1500 RPM | Turbocharged & Water-Air Intercooler | 13.9 : 1 | Direct Injection CMI PT |

| K38 – DM969 | 969 kW (1300 HP) @ 1800 RPM | Turbocharged & Water-Air Intercooler | 13.9 : 1 | Direct Injection CMI PT |

| KT38 – D(M)560 | 560 kW (750 HP) @ 1500 RPM | Turbocharged | 15.5 : 1 | PT |

| KT38 – D(M)679 | 679 kW (910 HP) @ 1800 RPM | Turbocharged | 15.5 : 1 | PT |

| KTA38 – D(M)664 | 664 kW (890 HP) @ 1500 RPM | Turbocharged & Water – Air Intercooler | 14.5 : 1 | PT Pump |

| KTA38 – D(M)768 | 768 kW (1030 HP) @ 1800 RPM | Turbocharged & Water – Air Intercooler | 14.5 : 1 | PT Pump |

| KTA38 – D(M)809 | 809 kW (1085 HP) @ 1800 RPM | Turbocharged & Water – Air Intercooler | 14.5 : 1 | PT |

| KTA38 – D(M)814 | 814 kW (1092 HP) @ 1800 RPM | Turbocharged & Water – Air Intercooler | 14.5 : 1 | PT Pump |

| KTA38 – D(M)880 | 880 kW (1180 HP) @ 1500 RPM | Turbocharged & Water – Air Intercooler | 14.5 : 1 | PT |

| KTA38 – D(M)1007 | 1007 kW (1350 HP) @ 1800 RPM | Turbocharged & Water – Air Intercooler | 13.9 : 1 | PT |

| ——END—— | ||||

General Information of CCEC K38 – DM969 Marine Auxiliary Engine |

|||||

| Engine Model | K38 – DM969 | Configuration | D233038MX02 | ||

| Curve No. | DM – 6883 | CPL Code | 3764 | ||

| Displacement | 2309 in3 / 38 L | Bore * Stroke | 159 mm * 159 mm / 6.26 in * 6.25 in | ||

| Fuel System | Direct Injection CMI PT | Cylinders | 12 | ||

| Prime Power | 969 kW (1300 HP) @ 1800 RPM | Aspiration | Turbocharged & Water-Air Intercooler | ||

| Rating Type | Prime Power | Overload | Rating Type | Prime Power | Overload |

| Rated Engine Power | 1300 HP / 969 kW | 1430 HP / 1066 kW | Rated HP Production Tolerance | ± 5 % | N / A |

| Rated Engine Torque | 3793 lb.ft / 5143 N.m | 4172 lb.ft / 5657 N.m | Governed Engine Speed | 1800 RPM | N / A |

| Brake Mean Effective Pressure | 248 PSI / 1708 kPa | 272 PSI / 1879 kPa | Idle Speed Range | 725 – 775 RPM | N / A |

| Piston Speed | 1875 ft/min / 9.5 m/sec | N / A | Compression Ratio | 13.9 : 1 | N / A |

| Friction Power | 170 HP / 127 kW | N / A | Piston Speed | 1R-6L-5R-2L-3R-4L-6R-1L-2R-5L-4R-3L | N / A |

| Steady State Stability Band at Constant Load | 0.25 % | N / A | Weight Dry – Engine Only | 4301 kg / 9482 lb | N / A |

| Maximum Torque Capacity from Front of Crank2 | 3202 lb.ft / 4341 N.m | N / A | |||

| ——END—— | |||||

System Technical Data of CCEC K38 – DM969 Marine Auxiliary Engine |

|||

| Fuel System | Prime Power | Overload | |

| Approximate Fuel Flow to Pump | 117.0 GAL/hr / 442.9 L/hr | 117.0 GAL/hr / 442.9 L/hr | |

| Maximum Allowable Fuel Supply to Pump Temperature | 140 °F / 60 °C | 140 °F / 60 °C | |

| Approximate Fuel Flow Return to Tank | 52.8 Gal/ hr / 199.7 L/ hr | 47.9 Gal/ hr / 181.3 L/ hr | |

| Approximate Fuel Return to Tank Temperature | 163 °F / 73 °C | 165 °F / 74 °C | |

| Fuel Rail Pressure | 143 PSI / 983 kPa | 166 PSI / 1145 kPa | |

| Average Fuel Consumption- Emissions ISO 8178 D2 Test Cycle | 34.9 Gal/ hr / 132.2 L/ hr | N / A | |

| Air System | Prime Power | Overload | |

| Intake Manifold Pressure | 58 in. Hg / 196 mm Hg | 62 in. Hg / 210 mm Hg | |

| Intake Air Flow | 2759 CFM / 1302 L/sec | 2866 CFM / 1352 L/sec | |

| Heat Rejection to Ambient | 6350 BTU/min / 112 kW | 6950 BTU/min / 122 kW | |

| Exhaust System | Prime Power | Overload | |

| Exhaust Gas Flow | 6901 CFM / 3257 L/sec | 7248 CFM / 3421 L/sec | |

| Exhaust Gas Temperature (Turbine Out) | 886 °F / 475 °C | 910 °F / 488 °C | |

| Exhaust Gas Temperature (Manifold) | 1158 °F / 626 °C | 1197 °F / 648 °C | |

| Heat Rejection to Exhaust | 44830 BTU/min / 788 kW | 47977 BTU/min / 843 kW | |

| Emissions (in accordance with ISO 8178 Cycle D2) | |||

| NOx (Oxides of Nitrogen) | 6.244 g/kW·hr / 4.656 g/BHP·hr | N / A | |

| HC (Hydrocarbons) | 0.352 g/kW·hr / 0.263 g/BHP·hr | N / A | |

| CO (Carbon Monoxide) | 0.804 g/kW·hr / 0.600 g/BHP·hr | N / A | |

| Emissions (in accordance with ISO 8178 Cycle E2) | |||

| NOx (Oxides of Nitrogen) | 7.094 g/kW·hr / 5.290 g/BHP·hr | N / A | |

| HC (Hydrocarbons) | 0.299 g/kW·hr / 0.223 g/BHP·hr | N / A | |

| CO (Carbon Monoxide) | 0.740 g/kW·hr / 0.552 g/BHP·hr | N / A | |

| Cooling System | Prime Power | Overload | |

| Sea Water Pump Specifications | MAB 0.08.17 – 07 / 16 / 2001 | N / A | |

| Pressure Cap Rating (With Heat Exchanger Option) | 15 PSI / 103 kPa | N / A | |

| Main Engine Circuit | |||

| Coolant Flow to Engine Heat Exchanger (with open thermostat) | 295 GAL/min / 1117 L/min | N / A | |

| Standard Thermostat Operating Range (Start to Open) | 180 °F / 82 °C | N / A | |

| Standard Thermostat Operating Range (Full Open) | 202 °F / 95 °C | N / A | |

| Heat Rejection to Engine Coolant3 | 403 kW / 22930 Btu/min | 437 kW / 24860 Btu/min | |

| Aftercooler (LTA) Circuit | |||

| Coolant Flow to LTA Cooler (with open thermostat) | 76 GAL/min / 288 L/min | N / A | |

| LTA Thermostat Operating Range (Start to Open) | 145 °F / 63 °C | N / A | |

| LTA Thermostat Operating Range (Full Open) | 175 °F / 80 °C | N / A | |

| Heat Rejection to Engine Coolant3 | 147 kW / 8370 Btu/min | 169 kW / 9610 Btu/min | |

| Maximum Coolant Inlet Temperature from LTA Cooler | 160 °F / 71 °C | N / A | |

| ——END—— | |||

Scopes of Supply of CCEC K38 – DM969 Marine Auxiliary Engine |

|||

| Exhaust System | 1. Silencer | Lubricating System | 1. Oil Pump |

| 2. Bellows | 2. Oil Filter | ||

| Fuel System | 1. Fuel Pump | Starting System | 1. Starter Motor |

| 2. Oil Cut Solenoid Valve | 2. Fywheel Housing | ||

| 3. Fuel Filter | 3. Flywheel | ||

| Charging System | 1. Alternator | Control System | 1.Stadnby Control Panel |

| Cooling System | 1. Seawater Pump | ||

| 2. Heat Exchanger | |||

| ——END—— | |||

Optional Accessories of CCEC K38 – DM969 Marine Auxiliary Engine |

|||

| Exhaust System | 1. Silencer | Power System | 1. Battery |

| Fuel System | 1. Float Fuel Tank | Cooling System | 1. Radiator |

| 2. Oil – Water Separator | 2. Cooling Fan | ||

| 3. Manual Fouling Pump | 3. Sea Water Pump | ||

| 4. Fuel Inlet and Outlet Hose | 4. Heat Exchanger | ||

| Remote Control System | 1. Sea Water Pump | ||

| 2. Heat Exchanger | |||

| ——END—— | |||

Committed to providing reliable premium propulsion system and power system for all kinds of ships around the world, SeaMac is a sub-brand of EMAC group that focused on maritime application. SeaMac’s ranges of products mainly inclduing marine main engine, marine gearbox, marine propellers, marine control lever system, marine auxiliary engine, marine generator set and emergency generator set.

For more information of our marine proplusion and power system products, you are welcome to visit SeaMac homepage: www.seamac.com

Modifiable components of CCEC K38 – DM969 Marine Auxiliary Engine |

||||

| Air Intake System | 1. Installation Position of Air Filter | Starting System | 1. 12 V Starter Motor for 12 V Electric System | |

| 2. Upgrade to Heavy – Duty Type Air Fitler | 2. Upgrading to Specified Brand and Speicifications of Starter Motor | |||

| Exhuast System | 1. Can Modify Installation Position and Direction of Turbocharger | Charging System | 1. 12 V Charging Alternator for 12 V Electric System | |

| 2. Water – Cooled Exhuast Manifold | 2. Explosion – Proof Charging Alternator | |||

| 3. Water – Cooled Turbocharger | 3. Upgrading to Specified Brand and Speicifications of Charging Alternator | |||

| Fuel System | 1. Upgrade to Fuel Fitler That Integrated With Fuel Transfer Pump and Fuel Pre – Hearter | Engine Auiliary Accessories | 1. Additional Auxiliary Systems Can Be Added for Special Applications | |

| Engine Shut-Down System | 1. 12 V Solenoid for 12 V Electric System | Cooling System | 1. Can Modify Engine Into Keel Cooling System | |

| 2. Explosion – Proof Solenoid | 2. N / A | |||

| Lubricating System | 1. Oil Pan Position | Power Output System | 1. Can Modify Size of Flywheel Housing and Flywheel. | |

| 2. Number of Dipstick | 2. Dual – Ear Flywheel Housing (for Twin – Starter System) | |||

| 3. Position of Dipstick Can Choose From 6 Positions | 3. Some of Models Can Modify Flywheel Housing Into Pto Integrated Type | |||

| 4. Can Modify Oil Filter to Be Remote Installation | 4. Engine Have Connecting Port of Ptos, That Able to Provide Power Output | |||

| Engine Mounting System | 1. Can Modify Engine Mouting Bracket | |||

| ——END—— | ||||

Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.

Engine Sale Manual

Installation Drawing

Installation Manual

Operation Manual

Parts Catalogue