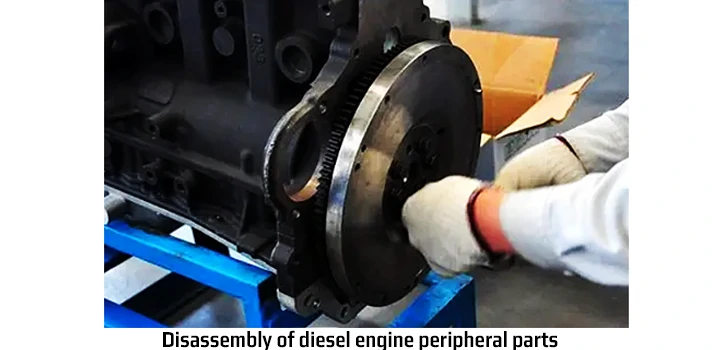

No matter how excellent the performance of the diesel generator set is, after a certain period of use, problems of one kind or another will occur. Some require minor repairs, and some require medium or major repairs. The disassembly and assembly skills of the diesel generator set are the basis for its maintenance. After the generator set is repaired, it must be debugged and tested to ensure that the generator set can achieve the desired performance. When dismantling various systems and parts of the diesel generator set if possible, special tools should be used as much as possible.

Preparation work before disassembly Disassembly is an important part of the CCEC generator set repair work. If the disassembly work is done well, it will create good conditions for future work. The disassembly of the generator set seems very simple, but if you do not pay attention to the technical details, the disassembly method of the parts, and the connection relationship between the parts, it will cause damage to the parts or other accidents. , affecting the normal progress of imaging workpieces, therefore, when disassembling the generator set, normal disassembly steps must be followed. In order to ensure the normal progress of disassembly and repair work, the following preparations should be made before disassembly.

Preparations before disassembly

1. Inspection before disassembly

The purpose of the pre-disassembly inspection is to understand the structural characteristics, worn parts and intentional parts of the generator set, and to initially determine whether the generator set needs to be inspected and repair scope, so as to be able to know the details and clarify the blindness of the repair work. Increase the initiative of repair personnel. In order to prepare materials and make repair plans in advance, the machine will not be shut down due to waiting for materials and accessories during the repair process, which will affect the normal progress of the repair work. The main contents of inspection before disassembly of the generator set include:

- Are the parts complete?

- Understand the structural characteristics

- Analyze the fault situation. Whether it is unstable speed, black smoke, insufficient power, or a loose cylinder, etc. must be clearly observed.

- Check its running time. If it is used for a short time, there will be few worn parts. On the contrary, if it is used for a long time, there will be many worn parts, so a comprehensive inspection should be carried out.

- Turn on the machine and test to see if there is anything wrong with the sound machine so that we can prescribe the right medicine.

2. Prepare various tools

- Commonly used repair tools include open-end wrenches, torx wrenches, adjustable wrenches, socket and kilogram wrenches, flat-mouth screwdrivers, cross screwdrivers, hand pliers, hand hammers and special pulling pliers, etc.

3. Arrange the workplace and workbench

The overhaul engine workbench is divided into upper and lower layers, and the vibration-disassembled parts can be placed below. There is a layer of mesh on top. The waste oil that flows out when the engine is disassembled can be separated from the engine very well. Parts can also be cleaned on the surface. Using this workbench can make the entire work environment tidier and cleaner. There is a black oil trap at the bottom of the upper layer, where the waste oil can be collected and cleaned regularly. The workbench is equipped with a stainless steel drawer, where tools, screws, screws, etc. can be placed at will. The workbench is also equipped with a retractable pneumatic tool interface, which can easily connect various pneumatic tools. Using this workbench can make the entire work environment tidier and cleaner. It is one of the essential tools in the maintenance workshop.

4. Prepare cleaning utensils and cleaning agents

The cleaning equipment usually prepared is an oil basin and a brush, and the cleaning agent is usually gasoline or diesel, but diesel is usually used more often, because gasoline can eas

5. Prepare repair parts

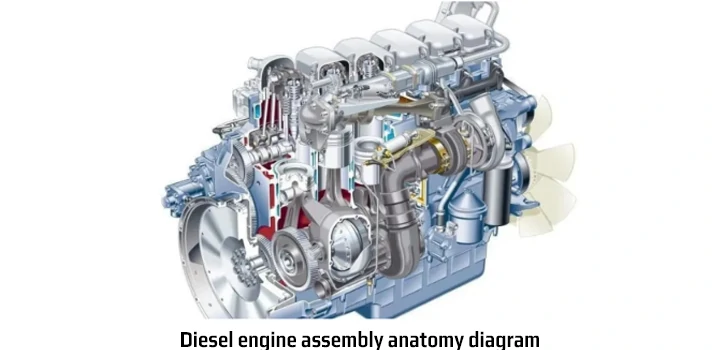

- The body components include the body (cylinder block, crankcase), oil pan, cylinder liner, cylinder head, etc.

- The crank-connecting rod mechanism includes the piston group, connecting rod group, crankshaft, flywheel, etc.

- The valve mechanism includes intake valves, exhaust valves, rocker arms, push rods, lifters, camshafts, etc.

- Intake and exhaust systems include air filters, intake pipes, exhaust pipes, exhaust mufflers, etc.

- The lubrication system includes oil cooler, oil pump, oil filter, etc.

- The cooling system includes radiator tanks, water pumps, fans, water inlet pipes, water outlet pipes, thermostats, etc.

- The fuel supply system includes fuel tanks, fuel transfer pumps, fuel filters, fuel injection pumps, governors, fuel injectors, high-pressure fuel pipes, etc.

- Electric starting system includes starting motor, battery, charging generator, regulator, etc.

cleaning method after disassembly

1.Scrub

- Put the parts into a container filled with diesel, kerosene or other cleaning fluids, scrub them with cotton gauze or brush them by hand. This method is simple and easy to prepare, but it is inefficient and is suitable for medium and small batches. Small seasonal pieces. Under normal circumstances, it is not advisable to use gasoline because it is fat-soluble and can damage the human body and easily cause fires.

2.Boil and wash

- Put the prepared solution and the parts to be cleaned into a cleaning pool of appropriate size welded with steel plates. There is a heating stove in the lower part of the pool to heat the parts to 80~90C for cooking and washing.

3.Spray cleaning

- The cleaning fluid with a certain pressure and temperature is sprayed onto the surface of the parts to remove oil stains. This method has good cleaning effect and high efficiency, but the equipment is complicated. It is suitable for cleaning parts with less complex shapes and serious grease on the surface.

4.Vibration cleaning

- It places the quarter parts of the wave cleaning machine on the cleaning basket or cleaning rack of the vibration cleaning machine, and submerges them in the cleaning liquid. The cleaning machine generates vibration to simulate the manual brushing action, and cooperates with the chemical action of the cleaning liquid. reach

For the purpose of removing oil stains.

5.Ultrasonic cleaning

- It relies on the chemical action of the cleaning fluid and the oscillation of ultrasonic waves introduced into the cleaning fluid to achieve the purpose of removing oil stains from parts.

In addition to the above various maintenance principles and disassembly methods, maintenance engineers must pay attention to the fact that the diesel generator set should be disassembled after cooling. First, it is easy to disassemble, and second, it prevents deformation during disassembly. Because the temperature is high, the rigidity becomes weak and easy to deform. The bolts on the machine body must be vibrated along the room to prevent breakage or deformation during vibration removal. After the diesel engine is decomposed, you need to use professional instruments to test each part. Most “old and healthy” people follow the inspection method to “see” or touch. For those who are new to the diesel engine or have insufficient experience, they need professional tools to test. In fact, This is also the most accurate and the method most advocated by CCEC.